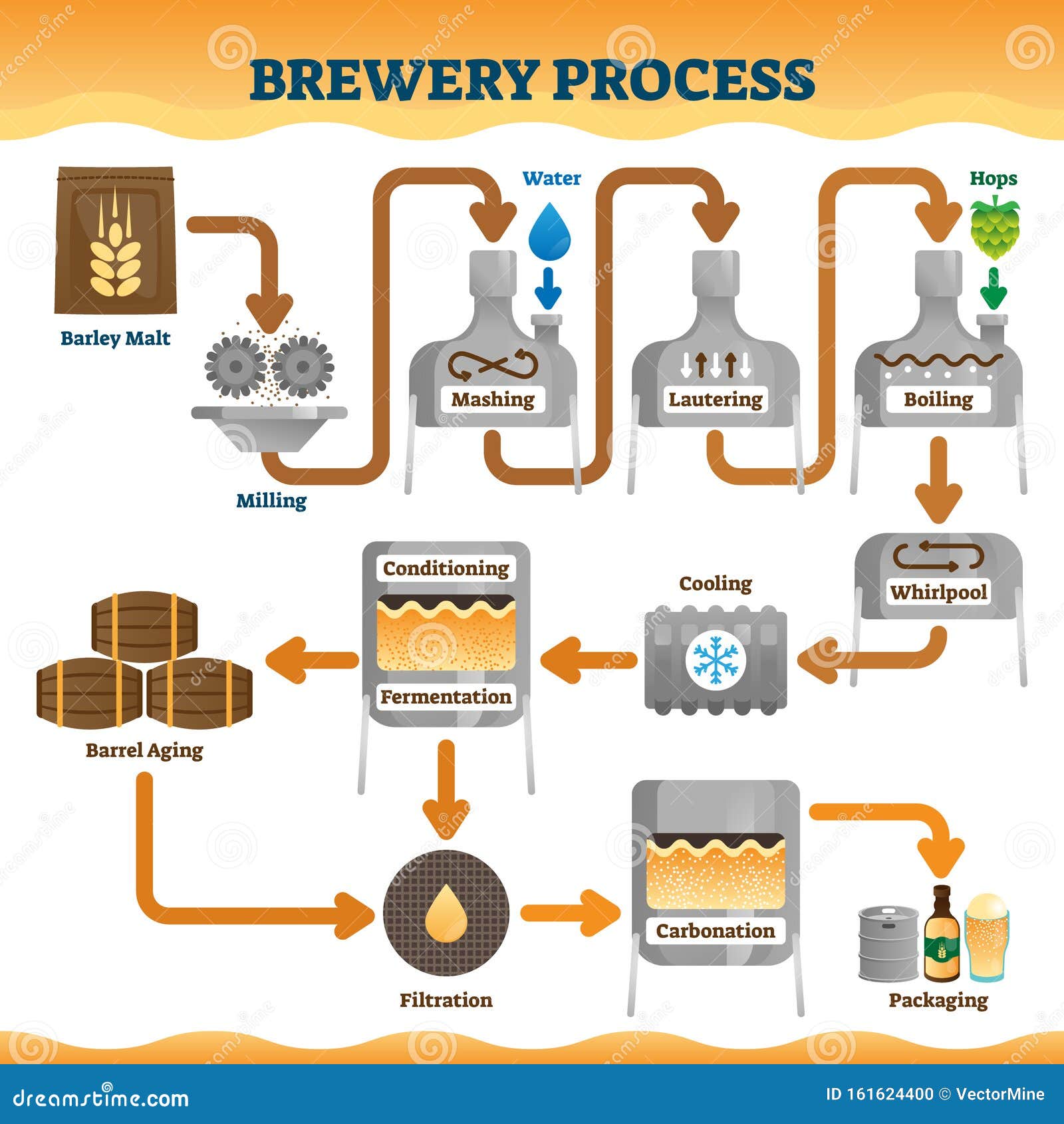

41 beer brewing process diagram

The Beer Brewing Process Explained. Beer brewing is essentially a biotechnological process, meaning the action of brewing and the making of beer depend on numerous enzymes and their reactions; microorganisms, including yeast, release these enzymes. The primary ingredients of beer are water, malted cereals (mainly barley), hops, and yeast. We are pleased to provide you with the picture named Beer Produce Diagram The Brewing Process.We hope this picture Beer Produce Diagram The Brewing Process can help you study and research. for more anatomy content please follow us and visit our website: www.anatomynote.com. Anatomynote.com found Beer Produce Diagram The Brewing Process from plenty of anatomical pictures on the internet.

The Fermentation Process [4] Fermentation is a very important process step in beer production. It is subject to alterations stemming from the variation in the yeast living organism and due to the complex raw materials of biological origin. The variability may manifest in the fermentation speed or cause off-flavors in beer.

Beer brewing process diagram

The Process of Brewing Beer. The Process of Brewing Beer Ingredients Water Malted Barley (the starch source) Brewer's Yeast Hops Other starch sources Corn, rice, sugar, millet, sorghum, cassava root, potato, agave Potato is used in Brazil Agave is used in Mexico Process Step 1: Malting Malting is the process where barley grain is made ready for ... Oct 02, 2017 · The beer is kept for aging from few months to few years followed by bottling and is then ready for commercial use. See How Beer Is Packaged/Canned With Flow Chart. Quantitative Parameters for Beer. Brewers considers these parameters to ensure the perfect beer brewing process. 1.Appearance. 2.Aroma. 3.Flavor. 4.Mouth-feel. 5.Alcohol Content : Beer is more than just water, hops, malt and yeast. In the beer making process various ingredients are mixed, processed and sometimes the structure of the raw materials is altered. The brewing process is made up of ten production steps from the fresh barley to the finished beer – we would like to present these steps in more detail.

Beer brewing process diagram. Brewing is the production of beer through steeping a starch (typically grain cereal) in water and then fermenting with yeast. The Brewing Process There are several steps in the brewing process, which include malting, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging. Jun 01, 2013 · The Brewing Process Diagram. Today’s infographic is another diagram of the Brewing Process, this one from the Beer Masons, a beer appreciation society in Australia. Click here to see the diagram full size. One interesting addition is they point out that beer is known by many names in the process from grain to glass, and list them in a flowchart. BREWERY— PROCESS FLOW DIAGRAMS 6 Process Flow Diagrams — Brewery A Typical Flowserve Pump Application for the Distillation Process 1. Feed pumps Centrifugal pumps for feeding the react to the distillation vessel 2. Heat transfer pumps Centrifugal pumps for handling high-temperature fluids 4. Cooling water pumps Centrifugal pumps for ... The process flow diagram below requires 6 hours to complete, a full 2 hours faster than the breweries that were collaborating on this project. For this to be possible, good timing and control is invaluable. Note: the brewing process will be covered briefly but the focus is placed on equipment and

In order to produce beer, barley is used which passes malting – a process that facilitates the germination of grain. After soaking barley seeds swell and chemical reactions start which causes starch-splitting to obtain malt sugar required for fermentation. Water. In brewing water is distinguished by contents and salt concentration. Brewery By-Products Process Flow Chart BREWERY TO LAUTERN TUN/MASH MIXER Notes This is the barley process flow. Oats, rice and corn follow similar process steps. Receipt of Malted Barley at Brewery Transfer of malted barley to malt silo Testing and Inspection Prior to Unloading Transfer of stored malted barley to mill START Malt Silo Lautern ... Beer is more than just water, hops, malt and yeast. In the beer making process various ingredients are mixed, processed and sometimes the structure of the raw materials is altered. The brewing process is made up of ten production steps from the fresh barley to the finished beer – we would like to present these steps in more detail. Oct 02, 2017 · The beer is kept for aging from few months to few years followed by bottling and is then ready for commercial use. See How Beer Is Packaged/Canned With Flow Chart. Quantitative Parameters for Beer. Brewers considers these parameters to ensure the perfect beer brewing process. 1.Appearance. 2.Aroma. 3.Flavor. 4.Mouth-feel. 5.Alcohol Content :

The Process of Brewing Beer. The Process of Brewing Beer Ingredients Water Malted Barley (the starch source) Brewer's Yeast Hops Other starch sources Corn, rice, sugar, millet, sorghum, cassava root, potato, agave Potato is used in Brazil Agave is used in Mexico Process Step 1: Malting Malting is the process where barley grain is made ready for ...

0 Response to "41 beer brewing process diagram"

Post a Comment